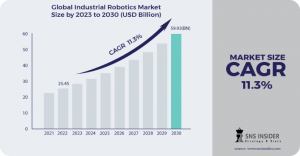

SNS Insider research highlights demand for collaborative robots across industries and the growing adoption of Industry 4.0 in industrial robotics market.

PUNE, MAHARASHTRA, INDIA, April 11, 2024 /EINPresswire.com/ — According to SNS Insider report Industrial robotics market, values was USD 16.87 billion in 2023, and its estimating to reach a USD 48.3 billion by 2031. This remarkable growth, projected at a CAGR of 14.01% over the forecast period (2024-2031), is fueled by several key trends.

Download Sample Report @ https://www.snsinsider.com/sample-request/1058

Market Report Scope

Industrial robots are programmable, multi-functional machines designed to automate production tasks in various industries. These robots boast reprogram ability, allowing for customization based on evolving needs. They are comprised of several key components, Provides power and motion to the robot. The integration of industrial robots fosters optimized manufacturing processes, promoting safety and efficiency. Rising labor costs and worker shortages are significant driving forces. For instance, in an effort to combat labor shortages, the UK chancellor invested in robotics to mitigate the economic strain caused by such challenges. Similar trends are expected in the US, with labor costs projected to increase, incentivizing industries to adopt robotics for cost control and workforce augmentation.

Companies are continuously innovating to develop robots with advanced technologies and features, catering to the demands of an increasingly complex industrial landscape. For example, Epson Robotics’ launch of the GX4 and GX8 SCARA robots exemplifies this trend, offering high-precision handling capabilities for intricate tasks. These advancements are poised to fuel market growth throughout the forecast period.

Market analysis

The Increasing Demand for electric vehicle (EV) Create a significant growth driver. As the demand for EVs surges, car manufacturers are increasingly relying on automated robotic systems for high-volume vehicle production. The electronics industry is recognizing the benefits of automation for achieving customization, similar to the established practices in the automotive sector. Robots can improve the entire production cycle, from assembly to palletizing. Advancements in end effectors and vision systems further enhance the value proposition of robotics in electronics manufacturing. Automation empowers human workers to focus on higher-level tasks, such as final inspection and quality control. Collaborative robots, specifically, offer flexibility and reusability, fostering human-robot collaboration for optimal production processes. The Asian electronics sector, a major global Region, is actively investing in robotics to maintain cost advantages amidst rising labor costs.

Get Discount @ https://www.snsinsider.com/discount/1058

The industrial robotics market faces two challenges, workforce skills and interoperability. Integrating robots necessitates upskilling the existing workforce in areas such as programming, maintenance, and troubleshooting specific to industrial robots. The automotive industry exemplifies this need, where collaborative robots necessitate training workers in collaborative and programming skills. Companies such as Audi have implemented comprehensive training programs to empower their workforce to work alongside robots, maximizing productivity. Interoperability, seamless communication between different automation systems, is crucial for smooth operations in factories. A modular framework is essential to ensure compatibility between software and hardware used for programming, monitoring, and troubleshooting. Integrating robots from different manufacturers and adapting them to changing production demands can be challenging, especially for small and medium-sized enterprises (SMEs) with limited technical expertise.

Segment Analysis

By Application

The Material Handling This segment holds the largest market share due to its extensive application in various industries for tasks like loading, unloading, and transporting materials.

By End User

The Food & Beverages segment is anticipated to exhibit the highest CAGR during the forecast period. Stringent hygiene standards, coupled with the need for increased production efficiency, are driving automation adoption in this sector.

By Application

Palletizing

Assembling

Welding

Material Handling

Painting

By Types

6-Axis Robots

SCARA

Cartesian

Articulated

Redundant

Delta

Dual-Arm and Parallel

By End-user

Entertainment

Electronics

Automotive

Rubber & Plastic

Food & Beverage

Pharmaceuticals

By Component

Robotic Arms

End Effectors

Drive Units

Robot Accessories

Controllers

Vision Systems

Sensors

Impact of Russia-Ukraine War:

The ongoing war between Russia and Ukraine has disrupted global supply chains, impacting the industrial robotics market, Sanctions imposed on Russia have restricted access to raw materials Important for robot manufacturing. The war has caused significant fluctuations in the prices of essential commodities like steel and semiconductors, impacting robot production costs. Uncertainties due to the war might lead some companies to postpone or reduce investments in automation projects, impacting market growth in the short term.

Impact of Economic Downturn:

Companies may become more cautious about capital expenditure during an economic downturn. This could lead to a decline in investments in automation projects, potentially slowing down market growth. Economic uncertainty might compel companies to prioritize short-term needs over long-term investments in automation. This could lead to a shift in focus towards cost-saving measures, potentially impacting on the adoption of industrial robots.

Regional Analysis:

North America Region contributes significant share of market because of The strong presence of major automotive and manufacturing companies, coupled with government support for automation initiatives, contributes to North America’s dominant market share.

Asia Pacific Region Fastest Growth Rapid industrialization, rising labor costs, and government initiatives promoting automation are propelling Asia Pacific’s growth as the fastest-growing regional market. China, Japan, and South Korea are expected to be at the forefront of this growth.

Key Takeaways for Industrial Robotics Market

Collaborative robots and Industry 4.0 adoption are shaping the future of industrial automation.

Advancements in robot technology and features are enhancing the capabilities and value proposition of robotics.

Workforce skills development and interoperability solutions are crucial for maximizing the benefits of industrial robots.

The Russia-Ukraine war and potential economic downturn pose challenges, but long-term growth drivers remain strong.

Buy Report @ https://www.snsinsider.com/checkout/1058

Recent Developments

May 2023: FANUC CORPORATION America introduced two new high-payload collaborative robots (cobots) at Automate 2023. These cobots boast increased payload capacities, showcasing their ability to handle heavier products.

May 2023: Yaskawa Electric Corporation announced a strategic partnership with Oishii Farm Corporation, a US-based strawberry producer. This collaboration aims to establish Yaskawa as a leader in agricultural automation by providing Oishii with automation solutions based on their “i³-Mechatronics” concept. This development highlights the expanding applications of industrial robots beyond traditional manufacturing sectors.

Akash Anand

SNS Insider Pvt. Ltd

+1 415-230-0044

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Instagram

YouTube

![]()

Originally published at https://www.einpresswire.com/article/702837083/industrial-robotics-market-is-boosted-by-usd-48-3-bn-driven-by-adaption-of-collaborative-robots-industry-4-0-by-2031